Customer Experience Is Quietly Designed Inside Your 3PL

As a China-based 3PL, I’ve noticed something that surprises a lot of ecommerce operators: the customer experience is often shaped long before a package ever moves.

Your buyers don’t see your warehouse rules, your routing logic, or your exception workflows—but they feel the outcomes as speed, consistency, and trust.

If you’re evaluating a fulfillment partner and trying to avoid “invisible” failures later, start with the decision lens rather than the sales lens.

This is exactly why I often recommend reading this first: Choosing a 3PL Partner.

It helps frame the real tradeoffs behind fulfillment performance.

At HUIXIN, we don’t treat customer experience as something you outsource. We treat it as something you can quietly undermine—or quietly protect—through operational design.

If you’re currently switching carriers or rewriting support macros to address complaints, it’s worth checking whether the underlying problem is actually upstream in your 3PL operations.

The Invisible Touchpoints Where 3PLs Shape Customer Experience

Inventory Placement: When “Fast on Average” Still Feels Slow

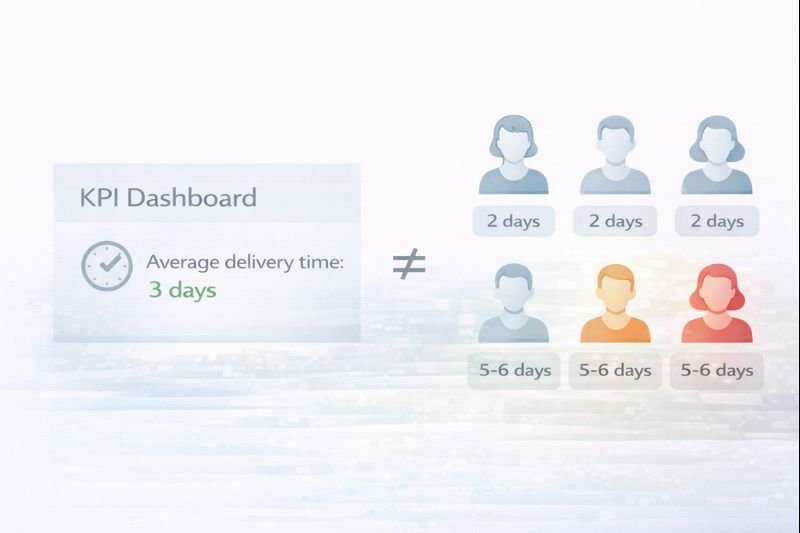

If you’re scaling cross-border ecommerce, you may be relying on “average delivery time” as your main signal that things are healthy.

But customers don’t experience averages—they experience their own deliveries.

One region consistently getting packages later than another will create a very specific kind of frustration: the feeling that your brand is unreliable, even if your dashboards look fine.

If you’re seeing region-clustered complaints, HUIXIN’s approach is usually to start with inventory placement before touching anything else.

We look at where demand actually comes from, which SKUs generate the most “late” perception, and whether your current distribution is creating systematic imbalance.

This is also where local 3PL fulfillment design matters, especially if your business spans multiple markets:

Local 3PL Fulfillment.

In practice, the fix is often smaller than people expect. If you’re currently treating all SKUs the same, we’ll help you identify the few products that create most of the perceived slowness—and redesign placement around those, not around theory.

Order Processing Speed: CX Damage Happens Before Shipping

If you’re dealing with “Why hasn’t my order shipped?” tickets, your customers are not complaining about transportation—they’re reacting to uncertainty.

The most stressful phase for a buyer is often the quiet period between payment and the first visible movement.

Even when final delivery is fast, slow order processing can make your brand feel unresponsive.

If you’re currently blaming carriers but support volume is rising, HUIXIN’s first move is to separate warehouse processing time from carrier transit time.

We map your cut-off logic, handoff timing, and exception handling to find where time is lost before labels are created.

This kind of operational diagnosis fits into the broader set of 3PL logistics insights you can use to prevent recurring friction:

3PL Logistics Insights.

The goal isn’t to claim “same-day shipping” in marketing. The goal is to make fulfillment behavior predictable, explainable, and consistent enough that customers stop feeling anxious.

Packaging Decisions Quietly Shape Trust

Packaging is often treated as a cost item until it becomes a customer experience problem.

But customers interpret packaging as part of your brand promise—especially when you sell higher-AOV products or anything fragile.

If you’re optimizing packaging for cost without SKU-level differentiation, you may be shifting risk from your operations into your reviews.

If you’re currently seeing damage claims or “arrived in poor condition” feedback, HUIXIN’s approach is not to push premium packaging universally.

We typically build SKU-level packaging rules so protection matches risk, and cost stays controlled where it should.

That balance is also tied to the hidden vs visible cost structure of any 3PL logistics cost model:

3PL Logistics Cost.

Last-Mile Routing: Cheap Decisions Can Become Expensive Experiences

Last-mile delivery is where many sellers feel the least control. Customers don’t care who the carrier is—they care whether your brand feels dependable.

If you’re choosing carriers purely by lowest cost, you can end up with performance volatility that shows up as complaint spikes in specific ZIP codes, not across your whole customer base.

If you’re seeing repeat issues in specific regions, HUIXIN usually avoids a full carrier overhaul first.

Instead, we look for targeted routing adjustments—keeping most of the network stable while rerouting only the high-risk segments.

This reduces visible failures without forcing you into a wholesale change that creates new instability.

If you’re comparing different provider models and why they behave differently operationally, you may find this useful:

Leading 3PL Providers.

Returns Handling: Where Trust Is Either Reinforced or Lost

If there is one moment customers use to decide whether they trust you again, it’s the return.

A late delivery may irritate them. A painful return often changes their future behavior.

When returns are routed internationally, processed slowly, or poorly synchronized with refunds, customers feel trapped.

If you’re noticing that customers who return are less likely to repurchase, HUIXIN’s approach is to treat returns as part of customer experience design, not a side process.

Local returns, clear receiving timelines, and refund coordination don’t eliminate cost—but they prevent trust from being silently consumed.

Why Sellers Often Misdiagnose Customer Experience Problems

If you’re attributing customer complaints to “peak season,” “unrealistic expectations,” or “carriers being unpredictable,” you’re not wrong—but you may be missing the structural part of the story.

From a 3PL operator’s perspective, recurring CX issues are often the result of systems optimized for averages and blind to edge cases.

At HUIXIN, we spend a lot of time helping sellers separate one-off incidents from repeatable patterns.

The goal is not to chase perfection. It’s to reduce the frequency of failures that customers interpret as a lack of reliability.

The Tradeoffs Hidden in Most 3PL Relationships

Every fulfillment setup involves tradeoffs: cost versus stability, standardization versus flexibility, speed versus predictability.

The difference is whether those tradeoffs are acknowledged early or discovered through customer complaints later.

If you’re currently evaluating a partner, HUIXIN’s approach is to make the tradeoffs explicit and operationally grounded.

That usually means discussing where variability comes from, what “good” looks like in your category, and what the real constraints are—before you sign anything.

Conclusion: You Can’t Outsource CX, but You Can Design Against Its Failure

Customer experience doesn’t live inside your 3PL, but it is deeply influenced by how your 3PL operates.

The brands that scale without eroding trust are not the ones claiming the fastest delivery on paper.

They are the ones reducing invisible failures—late-notice delays, confusing processing gaps, inconsistent packaging outcomes, and slow returns—before customers feel the need to complain.

If you’re looking at China-based fulfillment and want a partner that focuses on preventing these quiet failures, HUIXIN can walk you through the operational levers and tradeoffs in your specific model.

You can reach us here: Contact Us.